Lucite Vs. Acrylic: The Differences And Uses Of Both

Acrylic: it’s one of those words that’s become part of everyday life. Having said that, most of us would probably struggle to define exactly what it is. We just know what it looks like.

Lucite is a term that probably isn’t as familiar. What exactly is Lucite? And what’s the difference between Lucite and acrylic? Read on for our complete guide to Lucite vs. acrylic.

Getting to Know Lucite vs. Acrylic

Acrylic and Lucite are both transparent plastics developed as alternatives to glass. Like glass, you can use them in many different applications.

Here’s the first hurdle in differentiating Lucite vs. acrylic: all Lucite is acrylic, but not all acrylic is Lucite.

Acrylic is the broad term for a range of thermoplastics. Lucite is a type of acrylic, that is of particularly high quality. Acrylic is a generic term and is often marketed under the brand name Plexiglass.

On the other hand, Lucite—and this explains why we make a point of capitalizing the word— is actually a brand name. The chemical giant DuPont developed Lucite in the 1920s. They trademarked the name Lucite. When you consider that its chemical name is polymethyl methacrylate, you can see why they chose to market it as Lucite.

Broadway Opening Lucite Commemorative

Lucite Water Jug for Corporate Anniversary

Lucite vs. Acrylic: What’s the Difference?

While acrylic and Lucite are both transparent plastics, Lucite is the highest-quality acrylic. If you see that a deal toy or award manufacturer uses acrylic, that can have many meanings.

Acrylic comes in a range of different grades. Some offer outstanding clarity, scratch resistance, and strength. Other, lower grades of acrylic will only look good at first.

Over time, after maybe a year or so, you may notice that it starts to degrade. Rather than being crystal clear, your award or deal toy may take on a yellowish tinge. Not the look you were going for, and not the enduring impression you want to leave with a client.

If you want a deal toy or award that will stand the test of time, Lucite is the way to go.

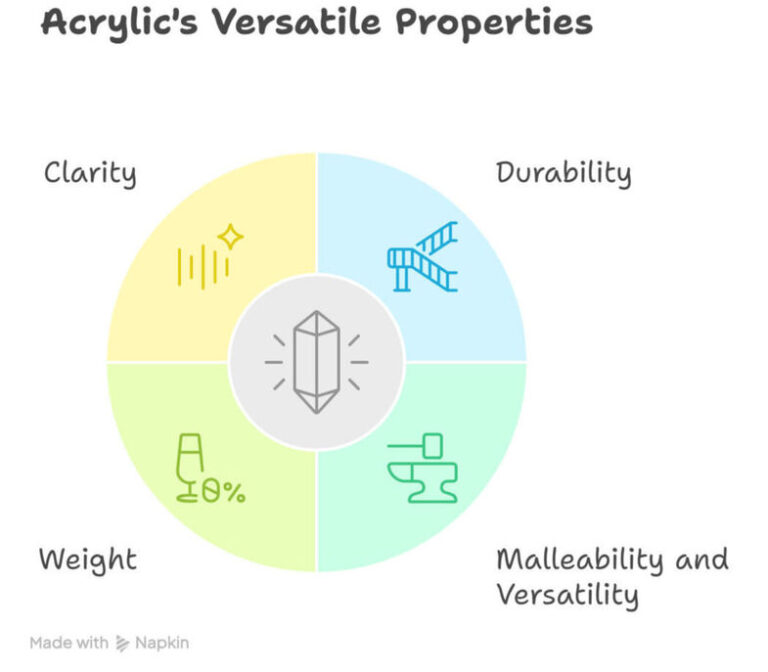

Qualities of Acrylic

Acrylic has a number of characteristics that have made it a more practical alternative to other materials such as glass over the years. Those characteristics include:

- Durability You probably see acrylic regularly used in security barriers and safety partitions, especially in settings such as airports, banks, and certain retail locations. The obvious concern here is safeguarding against bullets and other high impacts. When formed into sheets, acrylic can be extremely strong and stiff, while remaining clear. It’s also water-resistant, making it suitable for use in aquariums. Even submarine windows and airplane canopies can make use of acrylic.

- Malleability and Versatility Given this strength and durability, acrylic is nevertheless remarkably flexible. Acrylic is thermoplastic, meaning that you can subject it to high temperatures and mold it into a wide range of shapes. On cooling, it can also be drilled, machined, and sawed.

- Weight Despite its superior resilience and strength, acrylic weighs 50% less than glass. Its lower weight can translate into greater convenience and ease in using acrylic over glass in, for instance, the installation of skylights and windows.

- Clarity While it is superior to glass in its strength and resiliency, acrylic is equal to glass in light transmittance. It is also more fade-resistant than other plastics, insuring that it will maintain its effectiveness in applications such as automobile windows.

Special Qualities of Lucite

As mentioned previously, acrylic is a broad, generic term. Lucite, on the other hand, is a particular brand of acrylic. Lucite, therefore, shares all of the characteristics of acrylic noted above. But Lucite is also generally regarded as having qualitative advantages over other acrylic materials with respect to these features.

Lucite, for instance, has a higher refractive index than acrylic, giving it a clearer and brighter appearance. It’s also more resistant to UV light. This can be a significant point of differentiation since lower grades of acrylic can take on an unsightly yellow tinge from UV light exposure over time.

Uses of Lucite and Acrylic

Acrylic has a wide range of uses beyond deal toys and decorative items. Many people appreciate the aesthetic of acrylic furniture. Because of its transparency, acrylic can harmonize well with a minimalist, open plan and give an airy feel to an interior design. Interior furniture can include stools, chairs, dining tables, coffee tables, and shelves. It can also be used to provide a distinctive touch to more utilitarian items such as door handles and pulls.

But here again, terminology can be confusing. What’s often marketed as acrylic furniture is often actually Lucite. Lucite tends to be the favored material for furniture over other acrylics since it’s not only stronger and more durable but also easier to clean.

For outdoor furniture, which must likely sustain prolonged sun exposure, Lucite also carries the distinct advantage of higher UV resistance.

Jewelry & Artistic Uses

But Lucite wasn’t always just the material of choice for acrylic furniture. One of the original uses of Lucite was costume jewelry. Vintage pieces are now highly sought after and can be worth a lot of money. Jewelry makers appreciated its clarity, the fact that you can dye it easily, and it is easy to carve and polish.

Lucite is also an excellent medium for artists. That’s because it is highly sculptable and possesses unique ethereal qualities. People appreciate the play of light through the sculptures. This adds different dimensions depending on the angle of view.

A Lucite sculpture can make a stylish addition to any home. Artists exploit its ability to give dazzling transparency. They also appreciate its capacity to be dyed and made opaque, depending on the desired look.

Lucite can also be used to make hard-wearing door furniture. This includes door handles and knobs. They give the luxurious appearance of glass and can be custom molded into a huge range of shapes and styles.

Embedding Objects Inside Lucite and Acrylic

One prized characteristic of both acrylic and Lucite is their capacity to contain and showcase items. It’s therefore possible to “embed” actual items within a Lucite or acrylic design.

The piece shown above is a prime example. The Lucite honors the extraordinary efforts of emergency workers in restoring power in the wake of Hurricane Michael. Each piece incorporates a small section of the actual conductor wire workers used in repairing power lines.

But pieces incorporating embedded objects of this sort can also highlight the crucial difference between Lucite and some acrylics that were noted above. In cheaper, low-grade acrylics, these objects can take on the same yellowish haze over time.

The Lucite designs in the gallery below provide further examples of Lucite embedments. They demonstrate not only the capacity of Lucite to showcase embedded items, but also the diversity of materials that can be embedded.

Where Does Resin Fit in?

Resin is another commonplace term—and material– that also gets confused with both Lucite and acrylic.

Resins are natural and synthetic materials that are flexible and durable. They can be cast into different-shaped molds. Once the resin hardens using a catalyst, it is taken from the mold in its final shape. At that stage, the molded design is typically painted and assembled with other elements, as in the satellite-themed deal toy above.

Resin can be a great choice of materials for more complex designs. These designs typically are three-dimensional, and require a considerable amount of detail.

The capacity to bring to life highly customized and detailed designs has an obvious appeal. The drawback of selecting resin for an award or deal toy is that the process (especially the mold preparation) can be both labor-intensive and time-consuming.

Lucite vs. Acrylic: Which One’s the Winner?

If you’re looking for deal toys or awards, in the battle of Lucite vs. acrylic there’s only one winner: Lucite. Regular acrylic can be a versatile material, but it can present real pitfalls for deal toys and awards

For one thing, many acrylics used for deal toys and custom awards—acrylics that are of a lesser quality than Lucite— can yellow and discolor over time, even as quickly as within a year.

You obviously don’t want a once-sparkling deal toy or award to turn dingy within months. What kind of impression does that convey to the recipient? Whether you’re providing custom awards or Lucite tombstones, the goal is to provide clients, employees, and team members with an enduring symbol of achievement and appreciation.

The Corporate Presence has over 40 years of experience. We create bespoke deal toys, tombstones, and awards for both financial institutions and corporate clients ranging from Fortune 500 companies to startups. We use a range of top-quality materials to fit your desired aesthetic.

Click here to request a quote for deal toys or awards today!

David Parry is the Director of Digital Strategy for The Corporate Presence, and for Prestige Custom Awards, a designer and provider of custom corporate awards ranging from creative employee and client recognition pieces to the N.F.L. Commissioner’s Awards, and ESPN’s ESPY awards.

Contact Us For a Quote Today

"*" indicates required fields