Custom Lucite Embedments: The Questions You Should Really be Asking

Custom Lucite embedments, as you may already know, offer an ideal way to preserve, showcase, and honor prized items and objects.

Unless you don’t know what you’re doing.

Or you don’t know enough about Lucite embedments to ask the important questions. Because the embedment process also offers a great way to singe, tinge, melt, mangle, and fry those same beloved objects.

Too often, the expertise offered up about the process is reduced to simple terms: yes or no.

Yes, this can safely be embedded; no, that won’t work.

Make no mistake: knowing what is and isn’t possible is a necessary starting point. And you should always have realistic expectations of whether something will hold up to the embedment process.

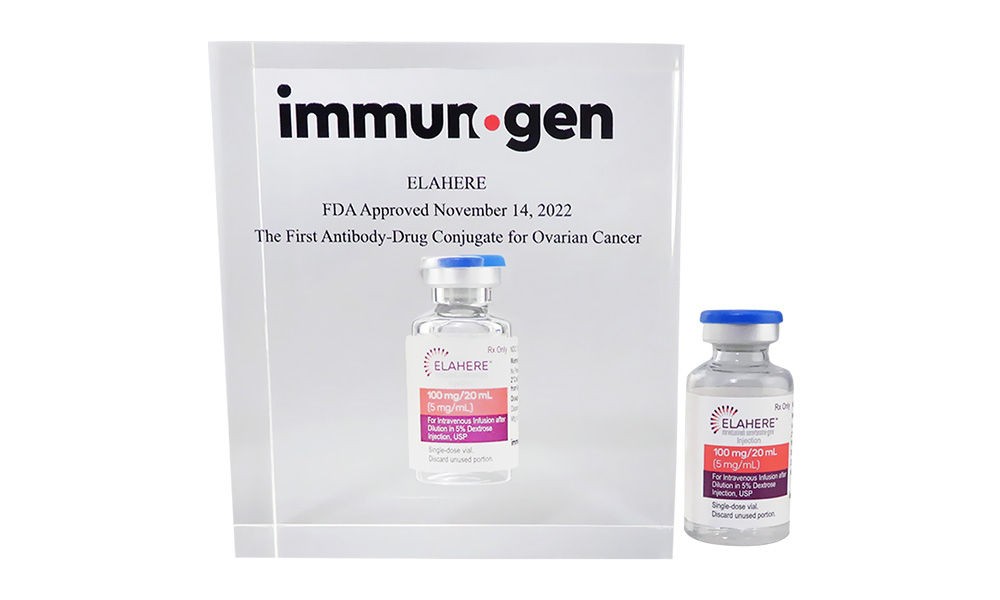

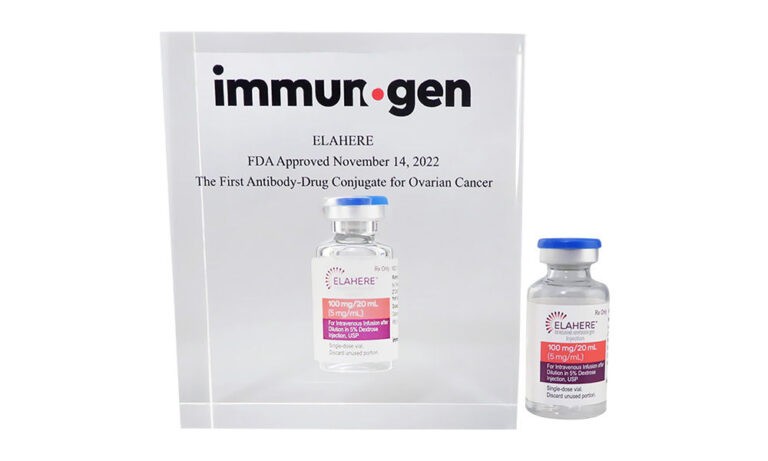

Placing something inside Lucite (acrylic) is always tricky. One of the biggest challenges here, for instance, isn’t the vial—but the label.

But embedding items in Lucite (acrylic) is actually a little more complicated than you might think.

First off, some things you’re likely to hear will seem completely counter-intuitive.

For instance, Lucite embedment involves extremely high heat (similar to baking something in a kiln). But if that’s true, why you can usually successfully embed a cookie but not a rock? And why do even related objects produce different results?

How is it, for instance, that peanuts typically embed? Almonds, on the other hand, typically do not.

But an answer to the question “Will this embed in Lucite?” is usually only part of the concern most people have, or should have, heading into the process. So what is it about custom Lucite embedments that most people are missing?

Embedding any product in Lucite—especially one as iconic as this bottle—should truly showcase it. Otherwise, what’s the point?

Is Lucite Embedding Possible? There’s More to Consider

When it comes to Lucite embedments, there’s a whole qualitative aspect that tends to get overlooked.

Yes, you want an answer to the question “Will this embed?”.

But the expertise necessary to answer that question only goes so far.

Because what you’re probably really asking is, “Will the embedment truly capture the effect I’m hoping for?”

Here’s an example. Suppose you’re in the pharmaceutical industry and want to recognize a team for their contribution to the development of a new drug. The exact occasion might be the first successful in-human trial or FDA approval.

It would be great to hear that, yes, you can embed the vial in Lucite.

But is that really all that’s involved?

What if, as is often the case, you also want to make sure that the label on the drug vial is included in the embedment? After all, for you, this might be a crucial part of replicating the authentic look of the vial.

So what if, during a test embedment, the print on the vial fades or disappears? Or it slips off the vial?

Those are challenges that can be dealt with but, again, you have to be able to anticipate these kinds of problems.

And, again, you also need to know what you’re doing.

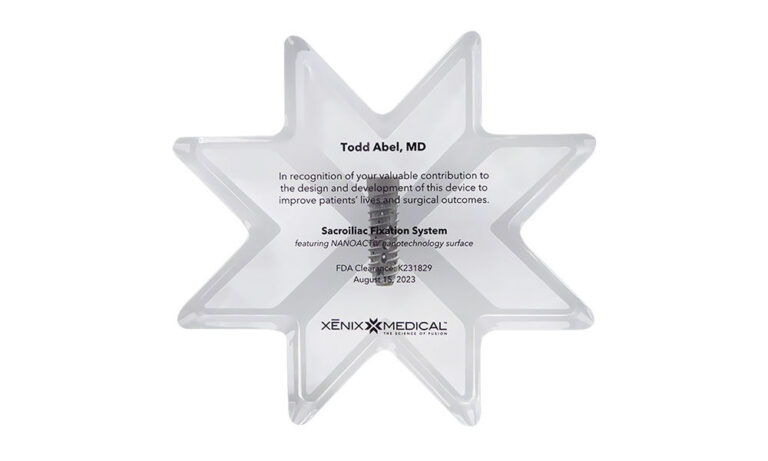

A great example of how embedding the real thing can transform the perceived value of a commemorative. What’s inside isn’t just some random piece of metal.

Why Perceived Value Matters in Custom Lucite Embedments

Here’s an example of how using a genuine article can heighten perceived value.

The piece above celebrates the extraordinary disaster recovery efforts of teams from PowerSouth in the aftermath of Hurricane Michael in 2018. Embedded within the piece is a section of the actual conductor strand used to restore power.

Another example involves embedments in the energy industry.

You might want to embed an oil drop, say to commemorate the “first” oil extracted from a site, or shipped from a port.

Yes, it’s possible to embed an oil drop. You can see oil drops inside Lucite all over the place online.

But what if you want to embed “your” oil? Do you really have to use the same generic “oil” that’s been used for every other project (and will for all future projects)?

After all, this does commemorate something to do with a specific oil. Wouldn’t using some interchangeable inky substance (which often isn’t even oil) undercut the impact of the commemorative?

Here again, the use of the genuine object can transform the perceived value of the commemorative. Here it’s a design honoring contributions to the development of a new surgical implant—with a design incorporating the actual implant itself.

The goal of any recognition gift or award is pretty straightforward: perceived value.

You want the recipient or honoree to attach value to whatever it is that’s being given—to recognize that his or her contribution or achievement has truly been appreciated.

And yes, you can use your own oil. But you have to be aware of that the option exists, and that the vendor you choose has the capabilities to do exactly that.

It Successfully Embedded! (But It Looks Lousy)

There are other some considerations that can also be figured in this “Will it embed?” question.

These involve aesthetic issues.

For instance, the chosen shape of the Lucite could either complement or undermine the embedment. And distortion could cause your drug vial, for instance, to end up looking more like a natural gas canister.

Also, you may have an object that successfully embeds in Lucite.

The only problem is that, when embedded, it looks terrible.

Just as an example, a banking customer of ours once wanted to embed an aircraft component manufactured by its client.

The client stressed that the part could withstand temperature extremes. It should therefore have absolutely no issues withstanding the extremely high temperatures involved in the Lucite embedment process.

Which proved to be true.

And the part did fully stand up to the heat. The only issue was that, once subjected to that high heat, it looked bad. This was, after all, an internal part not intended to be seen regularly.

So if your goal is to showcase one of your (or your client’s) cherished products, is showing something in this kind of tarnished condition really the best way to do that?

And if it isn’t, what do you do instead? What’s the Plan B?

A beautifully framed commemorative celebrating FDA approval of the drug Cosela.

Get Real Answers for Your Custom Lucite Embedments

Experience and expertise can go a long way. They can ensure that you do, in fact, get a correct answer to the question “Can I embed X in Lucite?”

At The Corporate Presence, we draw on more than forty years of experience in embedding objects in Lucite.

But we can also point to two other, equally important things we additionally bring to any project: design insight and production knowledge.When it comes to embedments, we know what works—both practically and aesthetically.

We also appreciate all the challenges—and the possibilities—of the embedment process, and are ready to share them with you.

Get your project started. Reach out to us today.

David Parry is the Director of Digital Strategy for The Corporate Presence, and for Prestige Custom Awards, a designer and provider of custom corporate awards ranging from creative employee and client recognition pieces to the N.F.L. Commissioner’s Awards, and ESPN’s ESPY awards.

Contact Us For a Quote Today

"*" indicates required fields